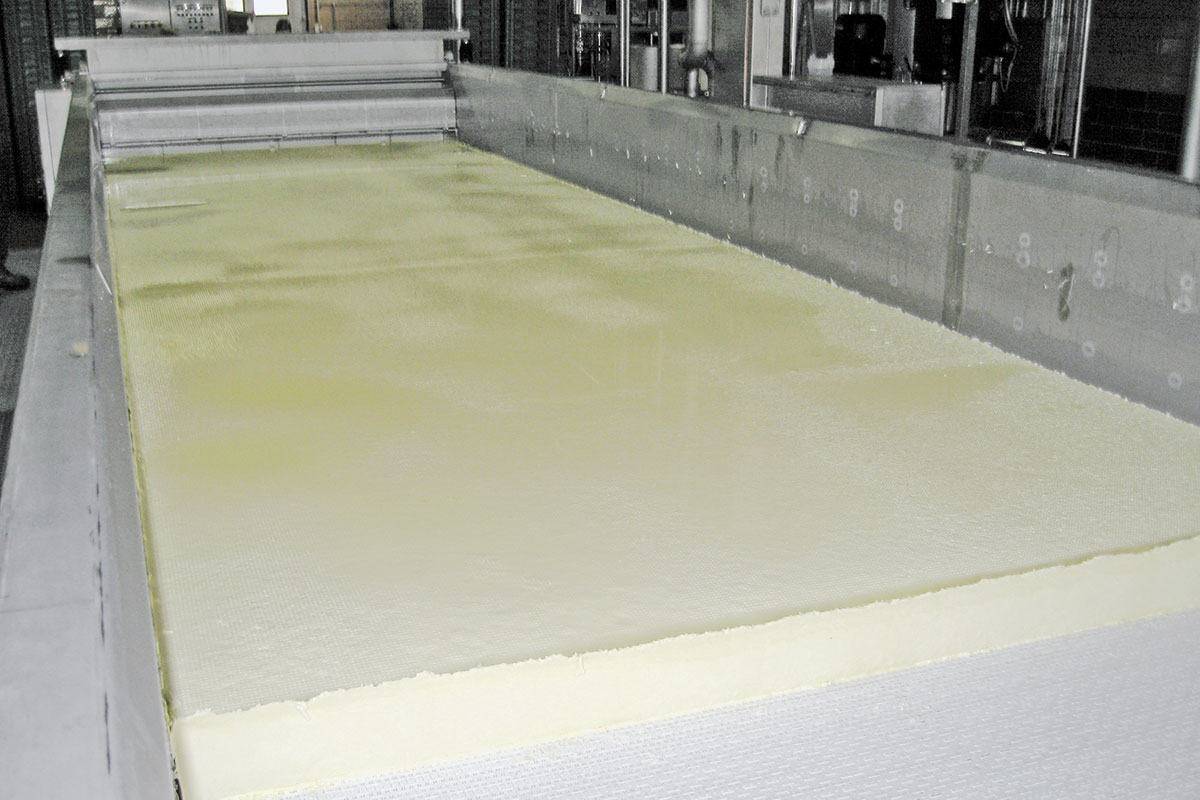

The variety of semi-hard cheese in dairy processing is huge and thus each product needs the tailored production system. As a manufacturer, you look for the most economically efficient solution for your particular product – from the milk delivery to the delivery of the cheese to retailers.

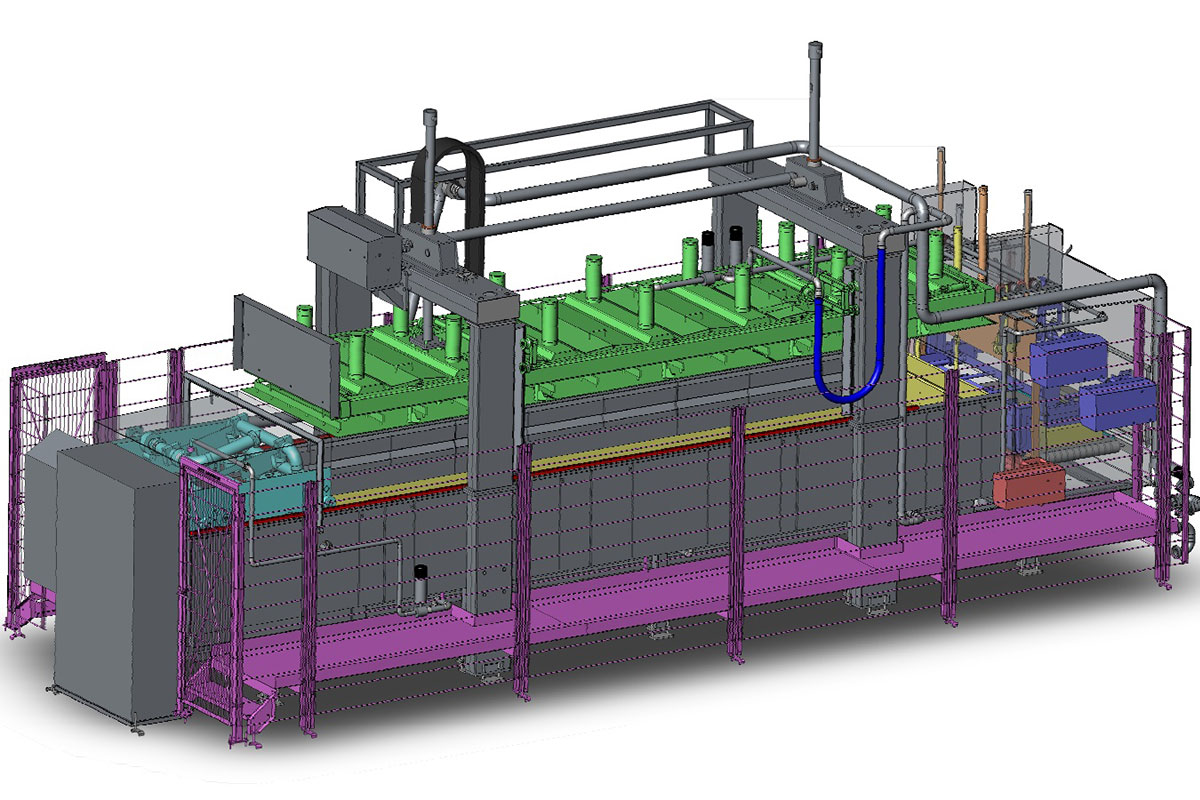

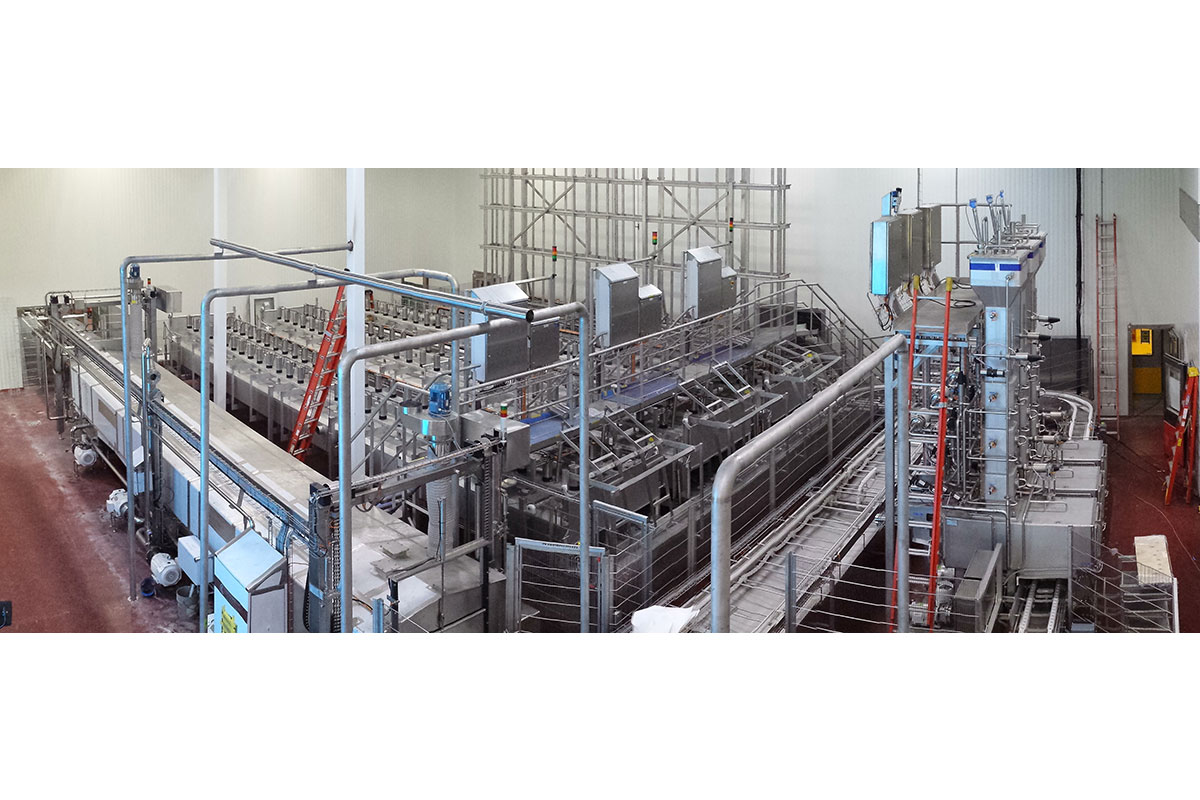

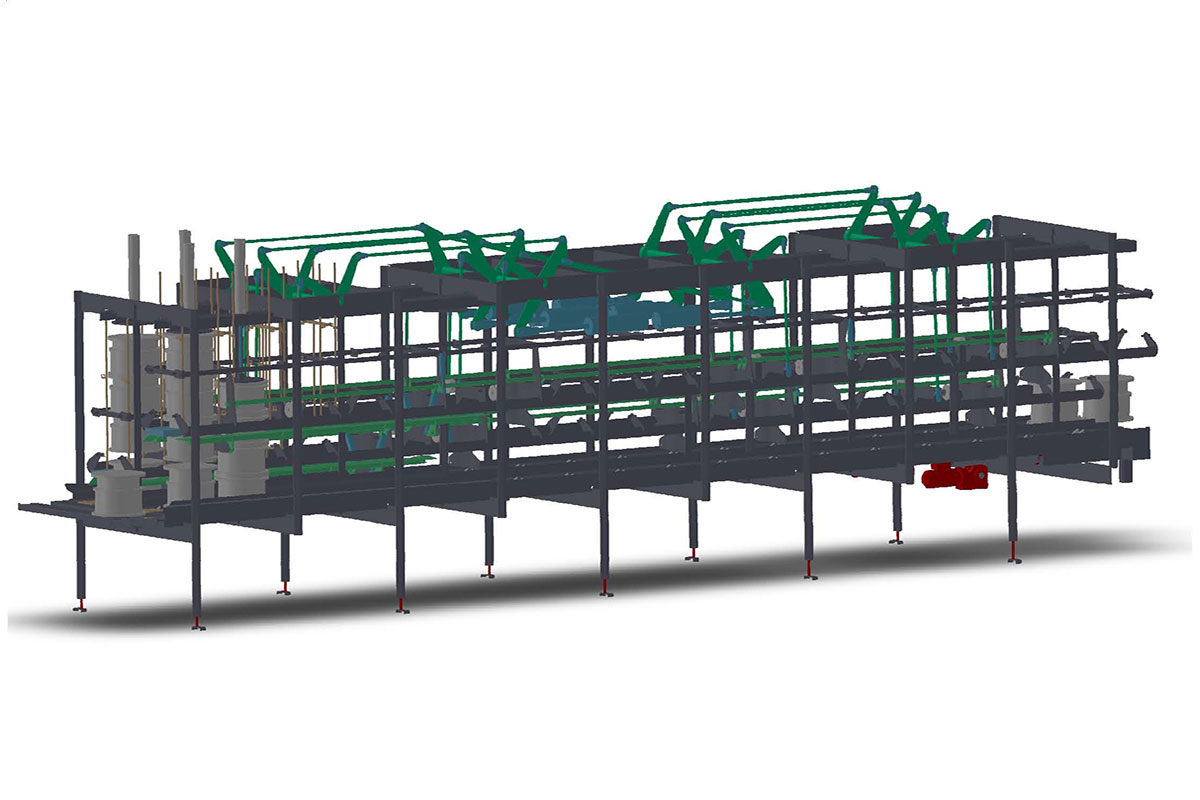

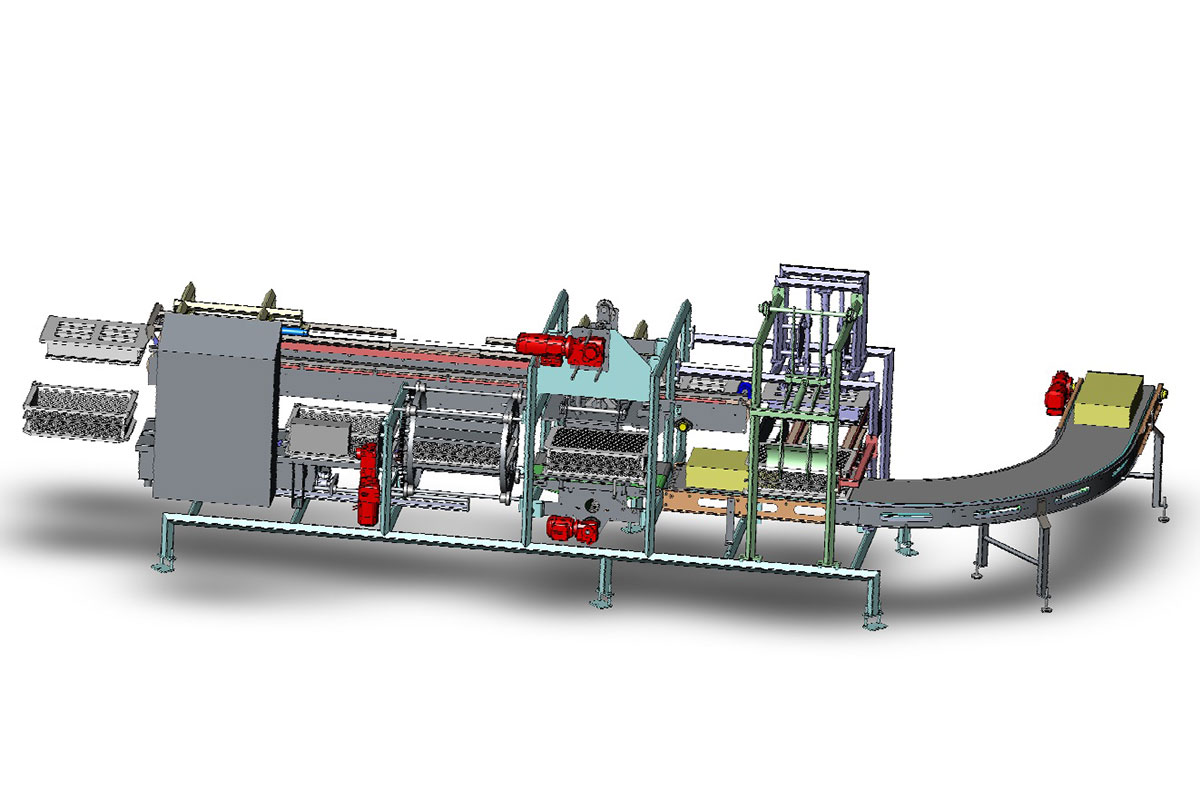

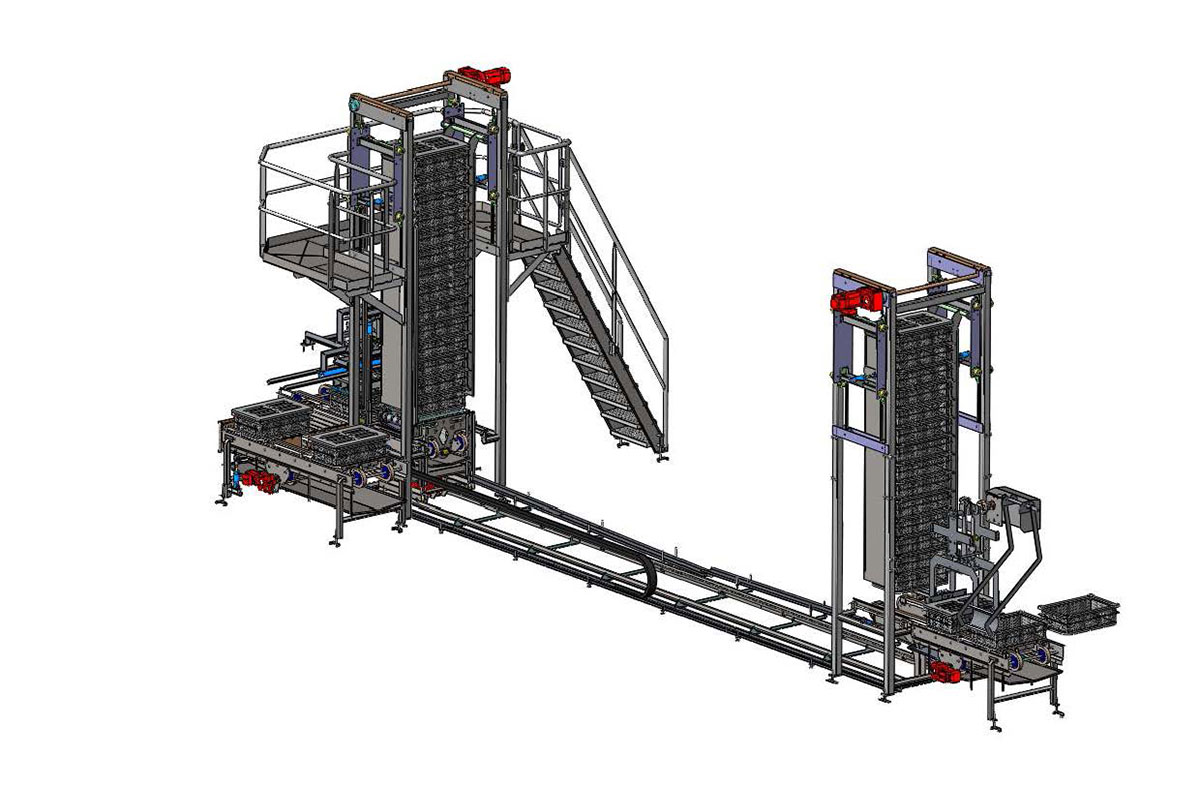

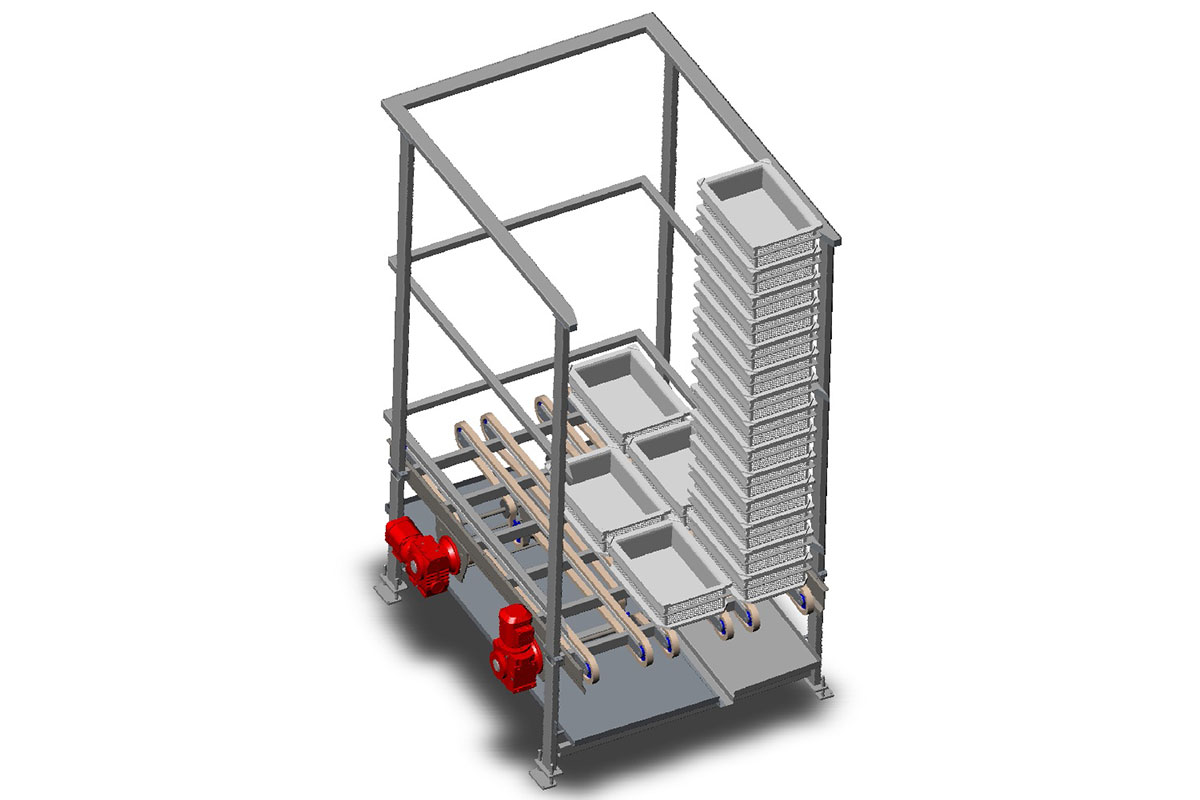

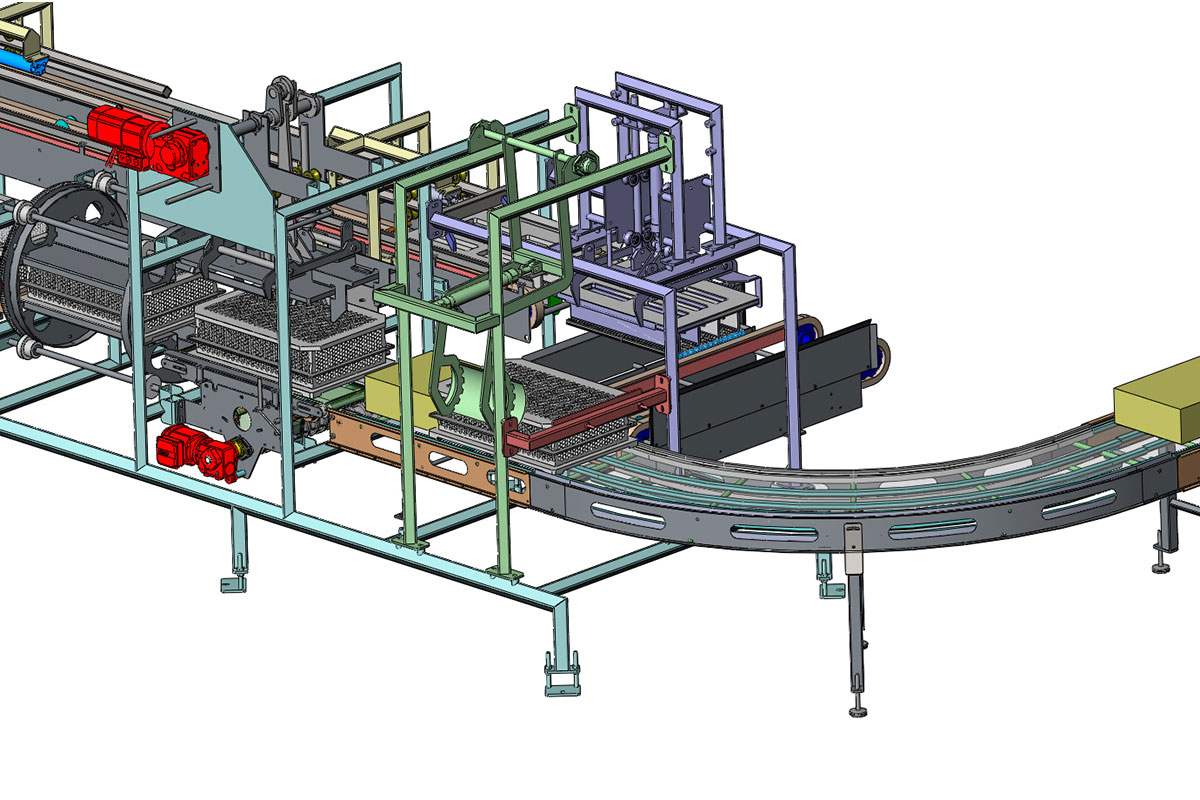

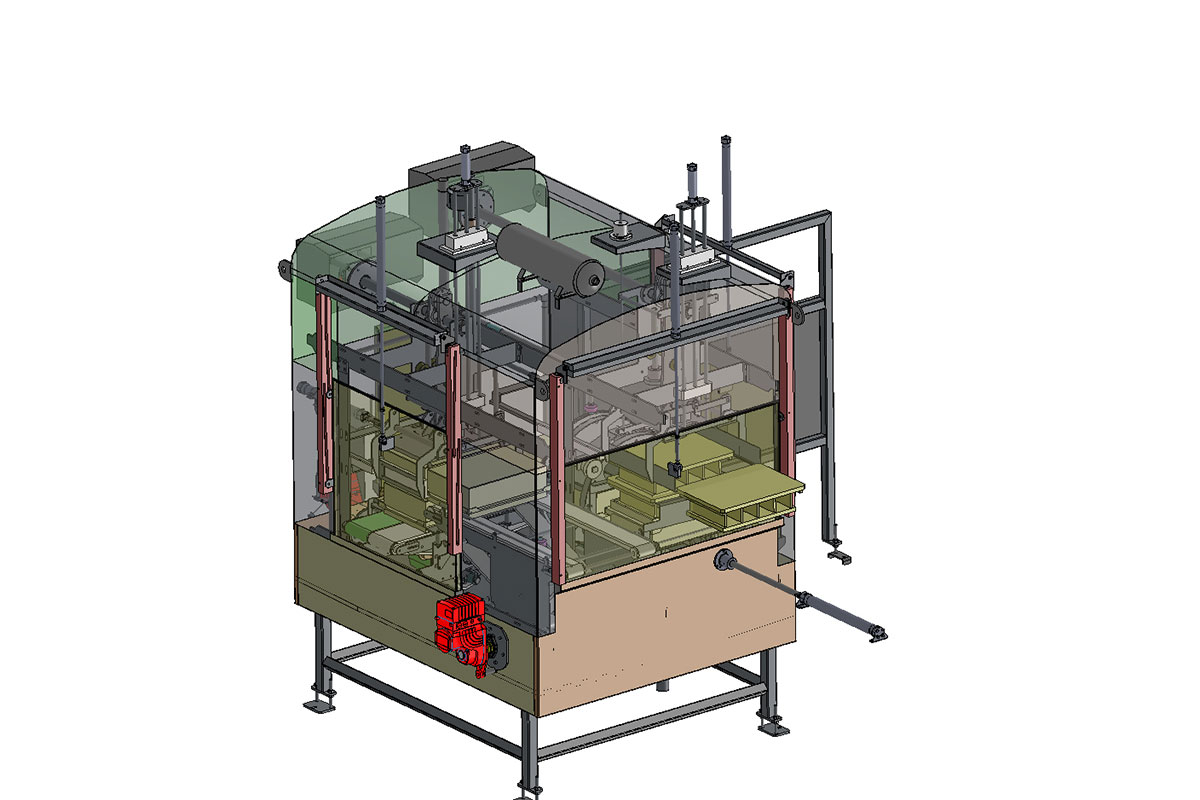

Sulbana offers comprehensive, state-of-the-art installation technology for processes. For the production of semi-hard cheese, we equip your company with elements such as cheese makers, pre-press vats, cheese vats, mould handling systems and washing machines.

Sulbana’s solutions for producing semi-hard cheese are characterised by:

- The highest standards of hygiene

- Fully-automatic systems

- Innovative cheese makers (various sizes and versions)

- Development of new filling and pre-press pans

- Robust cheese presses in modular design

- Solid and open design with selected materials

- Hygienically optimised conveying and logistics systems

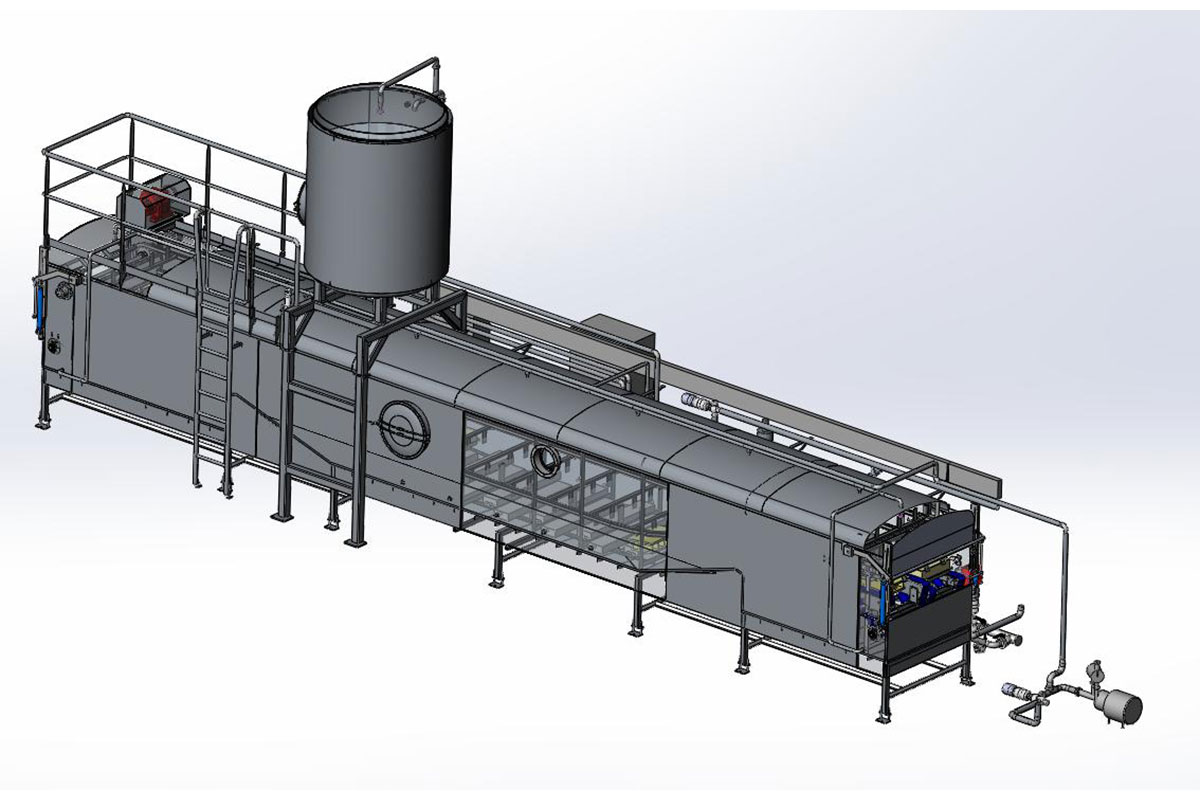

- Fully automatic tunnel washing machine for cleaning and disinfecting cheese moulds and lids

- Salt bath systems for large blocks

- Salt bath system with crane or immersion system