We are pleased to present you various new systems from our product range hygiene technology:

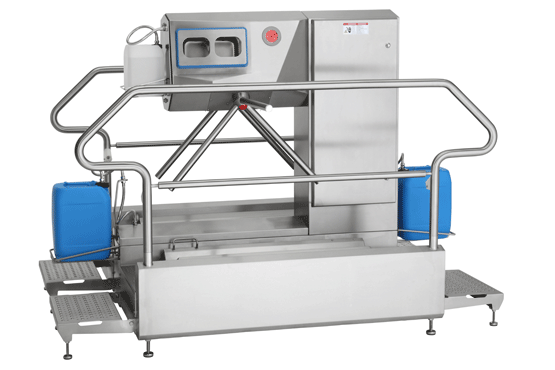

Inlet Complete Type 23761-23771

Step by step to optimal hand sanitation

Controlled process flow:

▪ Hand cleaning

2 versions:

Type 23761 with water/soap mixture

Type 23771 water/soap separated

▪ Hand drying with high performance hot air blower with integrated air filter F8 (optional also with paper dispenser)

▪ All-round hand disinfection with 4 spray nozzles

▪ Every step is visualized by an LED symbol light

▪ Potential-free contact to open automatic doors after completed sanitation process

▪ Units can be alternatively equipped with a two-arm turnstile supporting easier escape in case of emergency

▪ Option to connect time recording systems, signal horns, etc.

▪ Combinable with the ITEC Star Clean IV series

▪ Left- and right-hand version available

Star Clean IV Compact Serie

▪ Controlled process flow for hand and sole cleaning including disinfection

▪ Due to mandatory process flow, maximum hygiene is achieved before entering sensitive production areas

▪ Two tracks permitting access and exit for high personnel frequency

▪ The modular design permits customized solutions

▪ Depending on the available space, all variants can have a brush length of 1000 mm or 1600 mm

▪ Minimization of splashing water through pentagonal shaped step guide and optimized tread width

▪ The Star Clean IV Compact is available as a platform or built-in variant

▪ The platform versions can also be used as dry variants with dirt collection drawer (Bakery industry)

▪ The open hygienic design allows fast and efficient cleaning of all components

Hand dryer type Twin-Trock

Hygenic, effective, environmentally friendly hand drying

The new Twin-Trock is characterized by two integrated fans in the housing, which can be equipped with an optional F8 air filter for effective germ reduction. With two powerful warm air streams, the hands are dried in less than 10 seconds.

▪ Two fans in V-shape ergonomically arranged

▪ Non-contact activation

▪ Thermal fuse protects against overheating

▪ Automatic stop after 60 sec continuous operation

▪ Housing made of 1.5 mm ground stainless steel 1.4301

▪ Optionally with F8 air filter to reduce spores, bacteria and viruses

▪ Optional with collecting container incl. Drain valve for residual water

▪ Fast amortization through paperless drying

▪ High staff frequency with 2 turbo fans

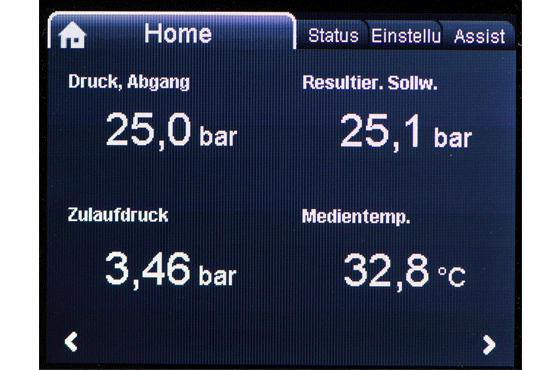

New pump generation for our low-pressure foam cleaning systems,

Booster systems, main stations, mobile devices

Our cleaning systems are equipped with the latest generation of stainless steel centrifugal pumps with the following advantages:

▪ Frequency-controlled pumps with the latest Grundfos blueflux® technology (IE5 motor)

▪ Dynamic pressure increase: Depending on the on-site inlet pressure, cleaning with up to max. 27 bar is possible

▪ The start / stop function of the systems is monitored by a flow switch.

▪ The systems are equipped with dry running and temperature monitoring.

Integrated color display with the following readable values:

▪ Output pressure

▪ Nominal value

▪ Inlet pressure

▪ Water temperature